Glass Reinforced Plastic (GRP) panels have become an integral part of modern water tank construction, offering high structural integrity, excellent durability, and enhanced insulation properties. This article delves into the advanced features of GRP panels, including their physical properties, stress resistance, and thermal insulation capabilities, making them the ideal choice for water tanks used in industrial and residential applications.

One of the most defining features of GRP panels is their superior physical properties, which make them highly resistant to stress, deformation, and environmental factors. Below are some critical parameters that set GRP panels apart from other materials used in water tanks:

| Test Item | Unit | Sample | Result | Test Method |

| Specific Gravity (23°C/23°C) | - | - | 1.806 | ASTM D792-13(Test Method A) |

| Water Absorption | % | - | 0.02 | ASTM D570-98(2010)e1 (24 h Immersion) |

| Tensile Strength | MPa | - | 115 | ASTM D638-14(*) |

| Tensile Elastic Modulus | GPa | - | 17.5 | ASTM D638-14(*) |

| Flexural Strength | MPa | - | 23.3 | ASTM D790-17(Procedure A) |

| Flexural Elastic Modulus | GPa | - | 15.9 | ASTM D790-17(Procedure A) |

| Shear Strength | MPa | - | 114 | ASTM D732-17 |

| Izod Impact Strength | J/m | - | 923 | ASTM D256-10e1 (Test Method A) |

| Compressive Strength | MPa | - | 234 | ASTM D695-15(**) |

| Thermal Conductivity (Mean Temperature 20°C) | W/(m.k) | - | 0.115 | KS L 9016: 2010 (By means of the Heat Flow Meter Apparatus) |

| Thermal Conductivity (Mean Temperature 20°C) | W/(m.k) | - | 0.024 | KS L 9016: 2010 (By means of the Heat Flow Meter Apparatus) |

| Barcol Hardness | - | - | 53 | ASTM D2583-13a |

| Glass content | % | - | over 42.9% | ASTM D2584-11 |

These properties are tested and validated according to international standards, ensuring the quality and longevity of GRP water tanks.

GRP Water Tank panels are designed to withstand stress and deformation, making them highly durable. Their special shape and high-pressure, high-temperature oil-hydraulic manufacturing process give them superior strength compared to traditional circular tank designs. These panels maintain high water pressure without dimensional deviations, even when exposed to extreme temperature variations.

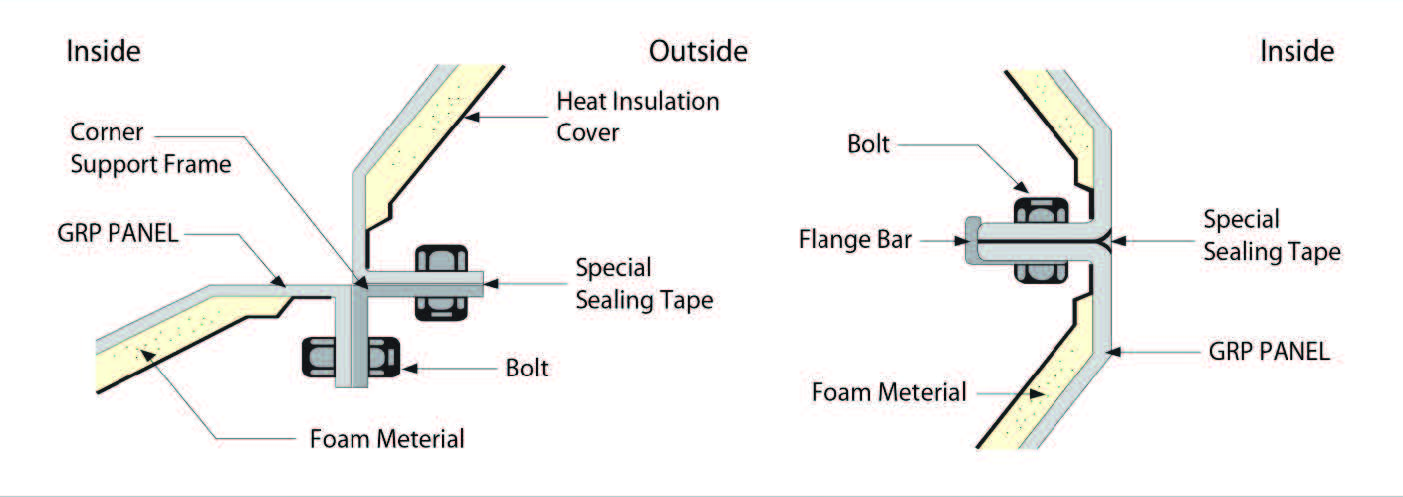

GRP panels are known for their superior heat insulation, which is critical in maintaining water temperature inside tanks. The advanced design of the joint parts and corner sections of the panel ensures minimum heat transfer, offering thermal stability and energy efficiency.

The following elements play a key role in their thermal insulation:

The insulation panel of a GRP water tank consists of eco-friendly polyurethane materials that prevent freezing and condensation. Inside the panel, non-woven fabric ensures adhesion and shape stability. Additionally, the 4-layer structure ensures optimal thermal performance, with panel thicknesses ranging from 40 to 50 mm for enhanced insulating capabilities.

GRP panels offer exceptional durability, stress resistance, and heat insulation, making them an ideal solution for water tanks. Whether for industrial or residential applications, these panels deliver long-term performance, reduced maintenance costs, and effective temperature management. With these advanced materials and manufacturing techniques, GRP water tanks are set to become the future standard for reliable water storage solutions.

Experience the brand Trusted by Renowned Companies across the GLOBE.

Pipeco stands at the forefront of the market, recognized as a premier manufacturer, supplier, and exporter specializing in top-tier GRP water tanks, stainless steel water tanks, and SMC manhole covers, FRP Water Tank, Fiberglass Tank, SMC Water Tank committed to delivering unparalleled quality and excellence.